Industrial Automation

Industrial Automation means making plant as much automatic as much possible or required. To achieve Industrial Automation we use DCS(Distributed Control System) or PLCs(Programmable Logical Control) & various instruments & VFD(Variable Frequency Drives to control machine motor speed).

To control the plant we must know what is the current status of the process for that we need to get Analog/Digital Inputs from plant, Analog inputs like Process Pressure, Temperature, Flow, Level, motor / turbine speed, & digital inputs like Buttons, limit switches etc which is considered as 0 or 1.

PLC( Programmable Logical Controller) is Microprocessor based Controllers which can be programmed to produce certain Analog/Digital Outputs based on Analog/Digital inputs. There are various PLC manufacturers like Siemens, Allen Bradley, Omron, ABB, Mitsubishi, GE etc.

PLC has following components Power Supply, CPU, Input Output Modules, Communication Processor Module

As per IEC 61131-3 control systems programming standard there are 2 textual programming languages: Structured Text; similar to Pascal) and Instruction List, as well as 3 graphical languages: Ladder Diagram(LD), Function Block Diagram(FBD) & Sequential Function Chart (SFC).

program is downloaded to the PLC directly or over a network. It is stored either in non-volatile flash memory or battery-backed-up RAM. In some programmable controllers, the program is transferred from a personal computer to the PLC through a programming board that writes the program into a removable chip, such as EEPROM.

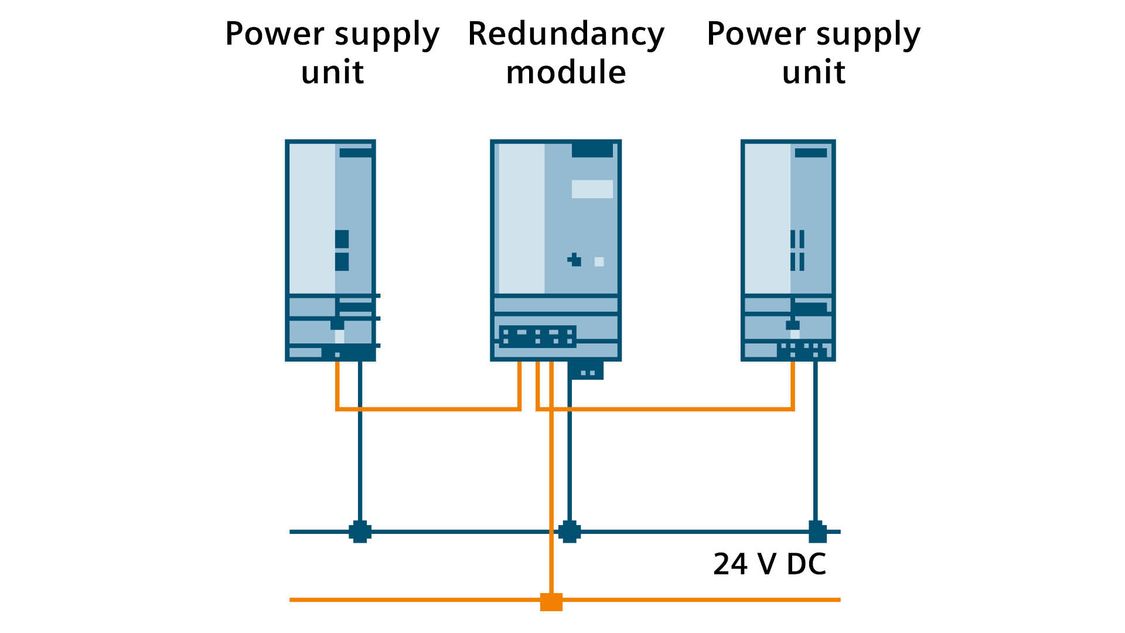

Redundancy in Siemens Power Supply

Question: Difference between Siemens S7 300 & S7 400 PLCs

Answer: S7-300 is a medium level PLC, and the S7-400 is a high-level PLC. So there are differences in work memory, processor speed, number of communication links and I/O connectivity.

First point, the S7-400 family is rack-based (Multi-pin backplane linking all modules, from power supply to I/Os) whereas the S7-300 is a bus-linked platform (a serial connector links all modules). So essentially the physical layout limits the S7-300 back[plane exchanges to MPI speeds (187,5 Bits per second), whereas the S7-400 uses parallel connections over the backplane rack, permitting higher exchange rates, and a higher module-density.

Second point, the form factor of the S7-300 is smaller, more compact than the S7-400, so this is something to take into account if space is a premium (inside a small machine panel, for example).

Now, the higher S7-300 CPUs (especiatlly for the new S7-317 and S7-319)have specs that approach (and sometimes pass) the specs of lower end S7-400 CPUs, so the distinction is starting to blur.

Foxboro DCS uses PACTware 3rd party software for FF device integration to the Foxboro Evo 2014 DCS. PACTware tool can be used to configure, operate, and diagnose all devices in a plant. PACTware supports all common communication protocols – regardless of the device type or task. PACTware member companies make the DTMs that are suitable for their devices available for download via PACTware. This means that you only have one contact person for the device, the appropriate driver (DTM), and PACTware. Service and support are also provided from a single source.

H2S detectors: Metal Oxide Semiconductor (MOS) Sensors

MOS sensing element includes a platinum heater element, an insulation medium

and the sensing element itself, which is a gas-sensitive resistive film When H2S comes into contact with this film there are measurable changes in the electrical conductivity. These changes are typically amplified in a transmitter device. MOS detectors have a long life compared to electrochemical sensors. change in oxygen levels may affect their output.

Electrochemical detector :

In an electrochemical sensor the cells combine enclosed electrodes and electrolyte. H2

S diffuses through a permeable membrane, the volume of H2 S increases in the air, an oxidation or reduction reaction occurs at one of the electrodes, and as a result, a linear current change occurs. High and low temperatures and the effect of humidity affect the detector’s performance. its Life will likely be affected due to evaporation of

electrolytes in dry, hot conditions. Extreme cold conditions may also reduce the detector’s speed of response

calibration, every six months

Optical H2S detector : Optical signal is absorbed by Gases, sensor will record the signal reduction and a micro-processor will calculate a corresponding gas value.

Analog Signal: Analog signals are input or output signals which continuously change and don’t have fixed values like 0 or 1.

Curve of analog signals are generally in Sinusoidal form.

Analog input signals are used to represent process variable’ s(Pressure, Temperature, Level, Flow etc) actual value.

whereas Analog output Signals are used to control Final element( e.g. Control Valve opening/closing, Motor speed etc)

for eg. 4-20 mA(milli amps) is analog signal which varies between 4 to 20 mA. Another analog signal is 0-10 Vdc which varies between 0 to 10 Vdc.

Digital Signal: Digital signals are the signals which has 2 fixed state either it would be 1 or 0.

Curve of digital signals are horizontal straight line.

eg. Of digital Signal is 0-24VDC either its value will be 0 or 24Vdc, 0 may be considered as OFF condition 24 Vdc may be considered as ON condition for any Digital Input signal or it can be used to Either Open/ Close any contacts in Relays/Contactors.

FAQs :

1. What is industrial automation?

Industrial automation is the use of control systems like PLCs, DCS, and VFDs to operate machinery and processes with minimal human intervention.

2. What is the difference between PLC and DCS?

A PLC controls specific equipment or processes, while a DCS manages multiple PLCs and systems across the plant for integrated control.

3. What are analog and digital signals in automation?

Analog signals vary continuously (e.g., 4–20 mA), while digital signals have two states — ON or OFF.

4. Why is industrial automation important?

Automation improves accuracy, safety, productivity, and reduces human error in complex industrial systems.

5. What are common automation tools?

Common tools include PLCs, DCS, SCADA systems, sensors, transmitters, and control valves.